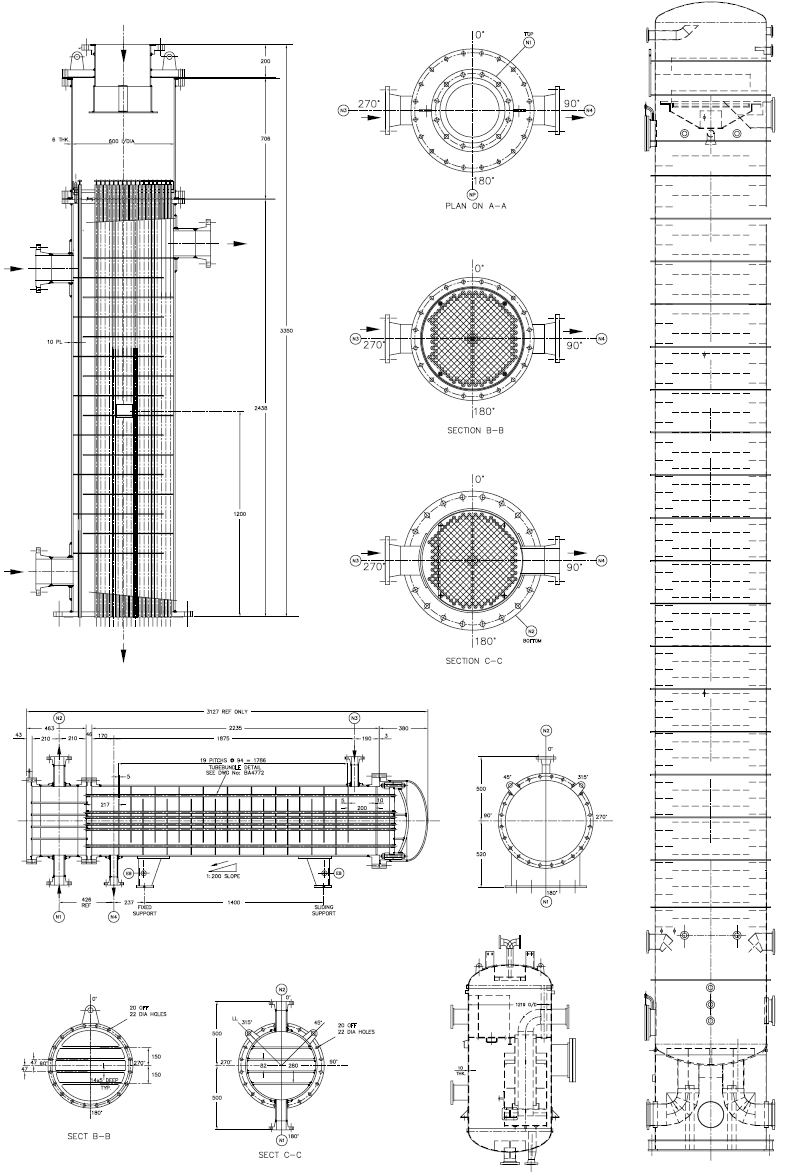

Pressure Vessel Design

Heat Exchanger Design

We provide pressure vessel design calculations and produce detail drawings. Pacific Engineering Pty Ltd has an experienced team of design engineers to design pressure vessels to AS 1210, AS 2809.1, AS 2809.6 (road tankers for cryogenic liquids) & ASME, shell and tube heat exchangers to TEMA, AS 1210 & ASME, transportable and cryogenic vessels to AS 1210, atmospheric storage tanks to API 620, API 650 & AS 1692 and produce detail drawings based on codes and client specifications.

We have developed a powerful software "AS 1210+" to speed up the design of pressure vessels and heat exchangers. The software has been exclusively designed for AS 1210 Pressure Vessels (Oct 2010 revision) and integrated with TEMA and ASME to assure accurate heat exchanger designs. Pressure Vessel Design Software "AS1210+" is developed and owned by Pacific Engineering Pty Ltd.

Pressure Vessel Design Software "AS1210+"

AS1210+ Pressure Vessel Design Software consists of a fully integrated suite of computer programs for use in the design and design verification of pressure vessels and shell and tube heat exchangers by Australian standards AS 1210 and international codes ASME & TEMA. The Pressure Vessel Design Software AS1210+ is developed to design a complete vessel, considering the entire vessel's effect on each of its components including wind and seismic loads (AS 1170.2, AS 1170.4). The main features of the software are:

Step-by-step design calculations of components for internal/external pressure, detailed printout,

Analysis of equipment subject to combined loadings including wind loads (AS 1170.2) and seismic loads (AS 1170.4),

External nozzle load calculations to WRC Bulletins 107,

Stress analysis of large cylindrical horizontal pressure vessels by the Zick method,

Flange and tubesheet thickness optimisation,

Tubesheet calculations to TEMA and/or ASME,

Detailed supports calculations,

AS 1210 & ASME material property data for all material types.

Some design projects we have completed include:

Diesel Tanks - Viva Energy

Hydrostatic Pressure Chamber - C2 Robotics Pty Ltd

Hydrostatic Pressure Chamber - Blueprint Laboratory Pty Ltd

Evaporator Surge Drum & Desuperheater Stand design - Raygen Resources Pty Ltd

Piping stress analysis, skid design - Calorifer Engineering AG

Horizontal Air Receiver - Thistle Fabrication Pty Ltd

18,000L Water Tank - Weld Class Eng Australia Pty Ltd

Plate exchangers - Heat Exchangers WA Pty Ltd

Water Separator - Driair International Limited

Mixing Tank - Luehr Filter Australia Pty Ltd

Lab Pilot Scale (50L) Pressure Vessel - Simulus Engineers & Simulus Laboratories

Heat Exchanger - DuPont Memcor (Australia) Pty Ltd

Cooker - Stainless Engineering & Maintenance Pty Ltd

Treated Water Tank - Stainless Tank & Mix Pty Ltd

Reactor - Borg Manufacturing Pty Ltd

Air Eliminator - Australian Fluid Transfer And Controls Pty Limited

Vertical Air Receiver - AJ Metal Products Ltd

Storage Tanks - Supagas

Vapour Condenser - Crossle-McKee Pty Ltd

6000L Tank with Trex Door - Precision Piping & Engineering Pty Ltd

200L Blast Unit - Oliver Technologies Pty Ltd

Crane Extension - Air Liquide Australia Limited

Regeneration Gas Heater - BOC Limited

Reservoirs - Wabco

Sludge Pre-heat Vessel - HydroMax Environmental

Boiler Flue Stack Design - O'Brien Boiler Services

Pneumatic Cylinder - ICON Engineering Pty Ltd

20L Air Bottle - Stainless Tank & Mix Pty Ltd

Knock Out Drum - Zeeco Inc

Reactor inlet Gas Filter - Stainless Tank & Mix Pty Ltd

Dosing Tank - Stainless Tank & Mix Pty Ltd

PR Station Vent Silencer - dbAcoustics Pty Ltd

Vertical Separators - Farley Riggs Pty Ltd

Helium Compressor Oil Cooler - ANSTO

Kettle Reboiler - APT Engineering (Aust) Pty Ltd

Ethylene Vessel - Stewart Tool Company

Load Cell Lugs - Unilever / GEA

4000L Tanker - Precision Piping & Engineering Pty Ltd

Blast Unit, 200L - Oliver Technologies Pty Ltd

Regeneration Electrical Gas Heater - BOC Limited

Self-supported Enclosed Flare Stack - ZEECO, INC - New Hope Corporation Limited

Ethylene Vessel - BECHTEL / STEWART TOLL CO - Australia Pacific LNG Project. Designed to ASME including Finite Element Analysis (FEA)

Water Dosing Tank - HYUNDAI / DESMO / SSTM - Goliat Oil and Gas Development Project - Norway designed to ASME

Expansion Tank - HYUNDAI / DESMO / SSTM - Goliat Oil and Gas Development Project - Norway designed to ASME

AS 1210-2010 Pressure Vessels was published in Oct 2010 to supersede the 1997 edition with its supplements and amendments.

The main changes in the new edition are the revision of design tensile strengths, revision of requirements for low-temperature service, revision of application of safety factors for flanges and transportable vessels, revision of bolted spherical type dished end calculations, revision of nozzle reinforcement calculations, tubesheet thickness calculations to ASME and the deletion of the 400mm manhole size.

Pressure Vessel Design Software "AS1210+" considers them all.

To request a quote and send files, please send an email to the email address provided below.